Polystyrene shapes

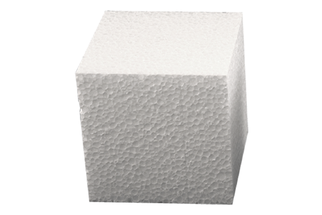

Expanded polystyrene (EPS) has been in use since the mid-1960s. Polystyrene is obtained by the polymerization of styrene. Expandable polystyrene (EPS) gets gas inclusions during the polymerization of solid beads. The beads are transported to the processor, where they are heated above 100°C under water vapor, the gas expands and the thermoplastic polymer puffs up. The edges of the bubbles fuse. The result is a moulded solid body, depending on the shape, everything is possible from simple plates to geometrical complicated mouldings.

Polystyrene:

Technical description: expanded polystyrene (EPS)

Raw material: styrene

Density: approx. 20kg/m3 | 20g/l)

Craft applications:

Napkin technique, various plugging techniques, decopatch, various painting techniques, paste, mottle